Source: bing.com

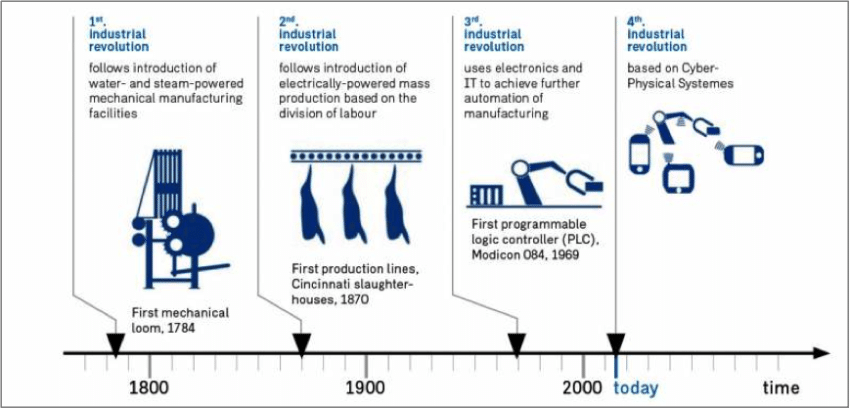

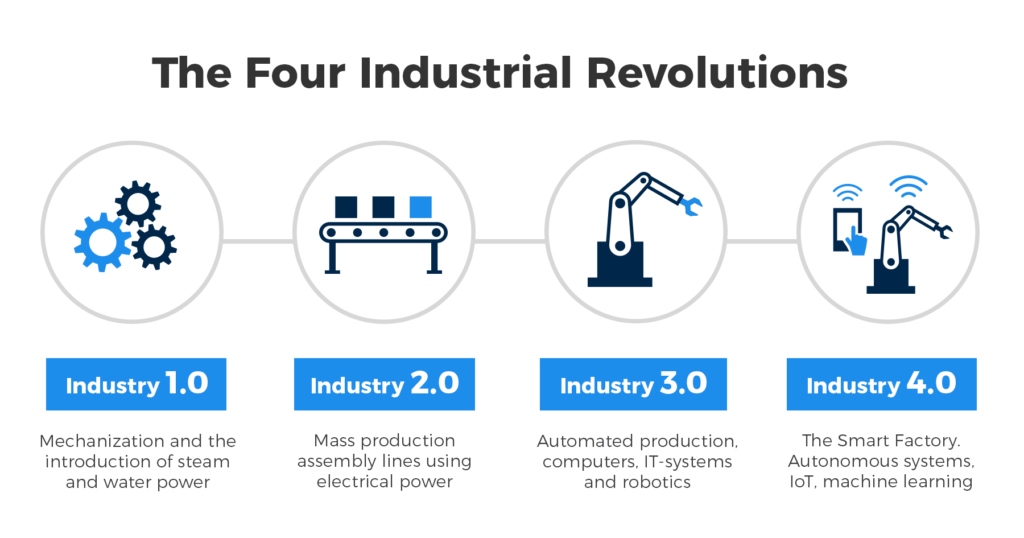

Source: bing.comManufacturing has come a long way since the Industrial Revolution. From the assembly line to lean manufacturing, advancements in technology have always had a profound impact on the industry. Today, we are on the brink of another revolution: Industry 4.0.

What is Industry 4.0?

Source: bing.com

Source: bing.comIndustry 4.0, also known as the fourth industrial revolution, is a term used to describe the current trend of automation and data exchange in manufacturing. It encompasses a range of technologies, including artificial intelligence, the Internet of Things (IoT), cloud computing, and robotics.

The Benefits of Industry 4.0

Source: bing.com

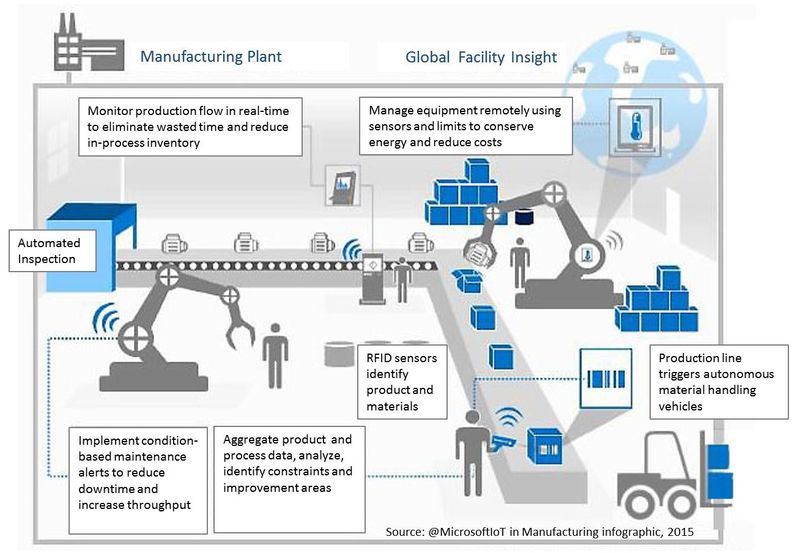

Source: bing.comThe adoption of Industry 4.0 technologies offers numerous benefits to manufacturers. These include increased efficiency, improved quality, reduced costs, and enhanced flexibility. By automating processes and using data to optimize production, manufacturers can streamline operations and respond quickly to changes in demand.

The Impact of Artificial Intelligence

Artificial intelligence (AI) is one of the key technologies driving Industry 4.0. By using machine learning algorithms, AI can analyze vast amounts of data and identify patterns that humans would miss. This can lead to improved product design, more efficient manufacturing processes, and better predictive maintenance.

The Role of the Internet of Things

Source: bing.com

Source: bing.comThe Internet of Things (IoT) refers to the network of physical devices, vehicles, and other objects that are embedded with sensors, software, and connectivity. In manufacturing, IoT devices can be used to collect data on production processes, monitor equipment, and optimize inventory management. This can lead to significant improvements in efficiency and cost savings.

Cloud Computing in Manufacturing

Source: bing.com

Source: bing.comCloud computing is another important technology in Industry 4.0. By storing data and applications in the cloud, manufacturers can access information from anywhere and collaborate with partners in real-time. This can lead to faster decision-making and improved supply chain management.

The Role of Robotics in Manufacturing

Source: bing.com

Source: bing.comRobotics has been used in manufacturing for decades, but Industry 4.0 is taking it to the next level. By integrating robotics with other technologies, such as AI and IoT, manufacturers can create more flexible and adaptable production lines. This can lead to reduced costs, improved quality, and increased productivity.

The Future of Manufacturing Jobs

Source: bing.com

Source: bing.comThe adoption of Industry 4.0 technologies has raised concerns about the impact on manufacturing jobs. While it is true that some jobs may be automated, the overall impact on employment is likely to be positive. By increasing efficiency and reducing costs, manufacturers can remain competitive and create new jobs in areas such as data analysis and robotics programming.

The Importance of Upskilling

Source: bing.com

Source: bing.comTo take advantage of the opportunities presented by Industry 4.0, it is essential for workers to upskill and adapt to new technologies. This will require investment in training programs and a shift towards a more collaborative and flexible work culture.

The Impact on Supply Chain Management

Source: bing.com

Source: bing.comIndustry 4.0 is also having a significant impact on supply chain management. By using IoT devices and other technologies, manufacturers can optimize inventory management, reduce lead times, and improve order fulfillment. This can lead to improved customer satisfaction and increased competitiveness.

The Role of Data Analytics

Source: bing.com

Source: bing.comData analytics is another key technology in Industry 4.0. By using advanced analytics tools, manufacturers can gain insights into production processes, identify areas for improvement, and make data-driven decisions. This can lead to improved quality, reduced costs, and increased efficiency.

The Impact on Product Design

Industry 4.0 is also having an impact on product design. By using AI and other technologies, manufacturers can create smarter, more innovative products that better meet customer needs. This can lead to increased sales and improved customer satisfaction.

The Role of Cybersecurity

Source: bing.com

Source: bing.comCybersecurity is an important consideration in Industry 4.0. With more devices connected to the internet, there is a greater risk of cyberattacks. It is essential for manufacturers to implement robust security measures to protect their data and systems.

The Impact on Sustainability

Industry 4.0 is also having an impact on sustainability. By using data to optimize production processes, manufacturers can reduce waste and energy consumption. This can lead to cost savings and a reduced environmental impact.

The Role of Government

Source: bing.com

Source: bing.comThe adoption of Industry 4.0 technologies will require significant investment from both the private and public sectors. Governments can play a role in supporting this transition by providing funding for research and development, offering tax incentives for companies that adopt new technologies, and investing in training programs for workers.

The Challenges of Industry 4.0

Source: bing.com

Source: bing.comWhile the benefits of Industry 4.0 are clear, there are also challenges that must be addressed. These include concerns about job displacement, cybersecurity risks, and the need for significant investment in new technologies and training programs.

Conclusion

Industry 4.0 is transforming the manufacturing industry in profound ways. By adopting new technologies and processes, manufacturers can improve efficiency, reduce costs, and create smarter, more innovative products. While there are challenges to overcome, the benefits of Industry 4.0 are too great to ignore.